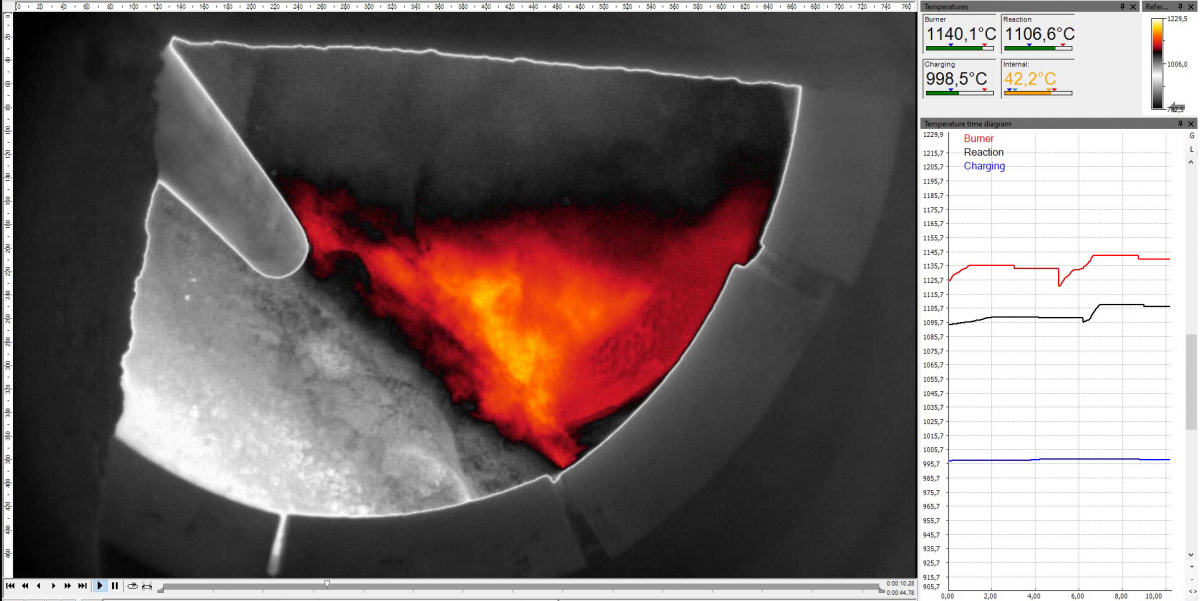

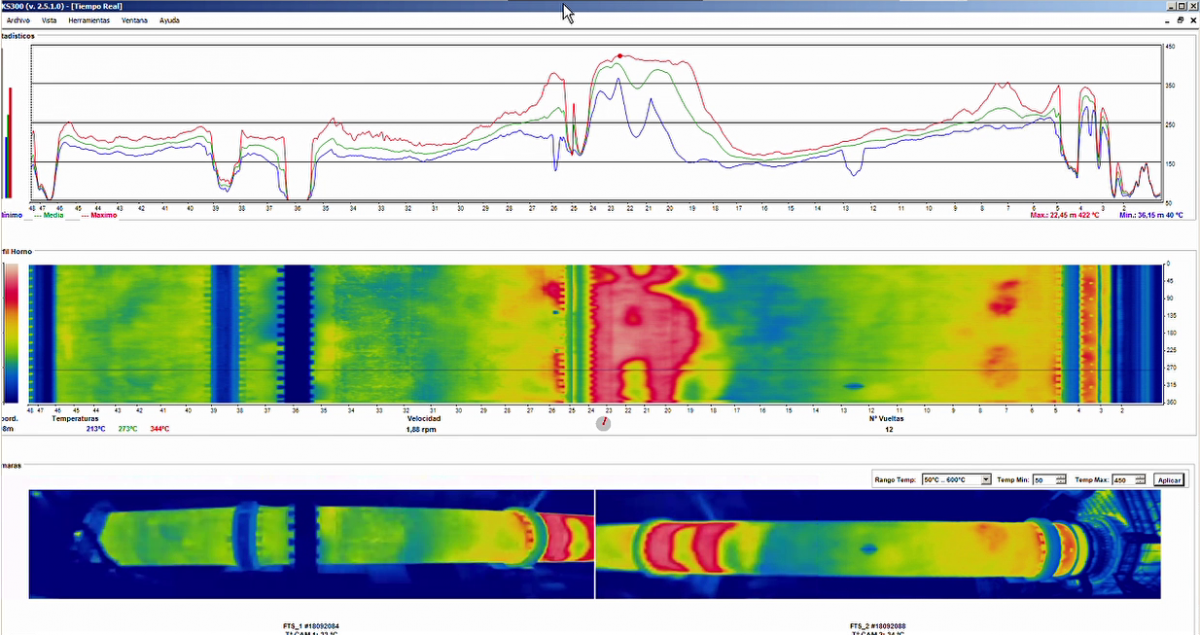

Production of lime requires burning the limestone at controlled, high temperature in a rotary kiln. Temperature measurement at key locations during operation of a kiln is important to maintain an optimum performance to minimise downtime.

VisionTIR offers different solutions to prevent damage to the kiln shell and ensure product quality.