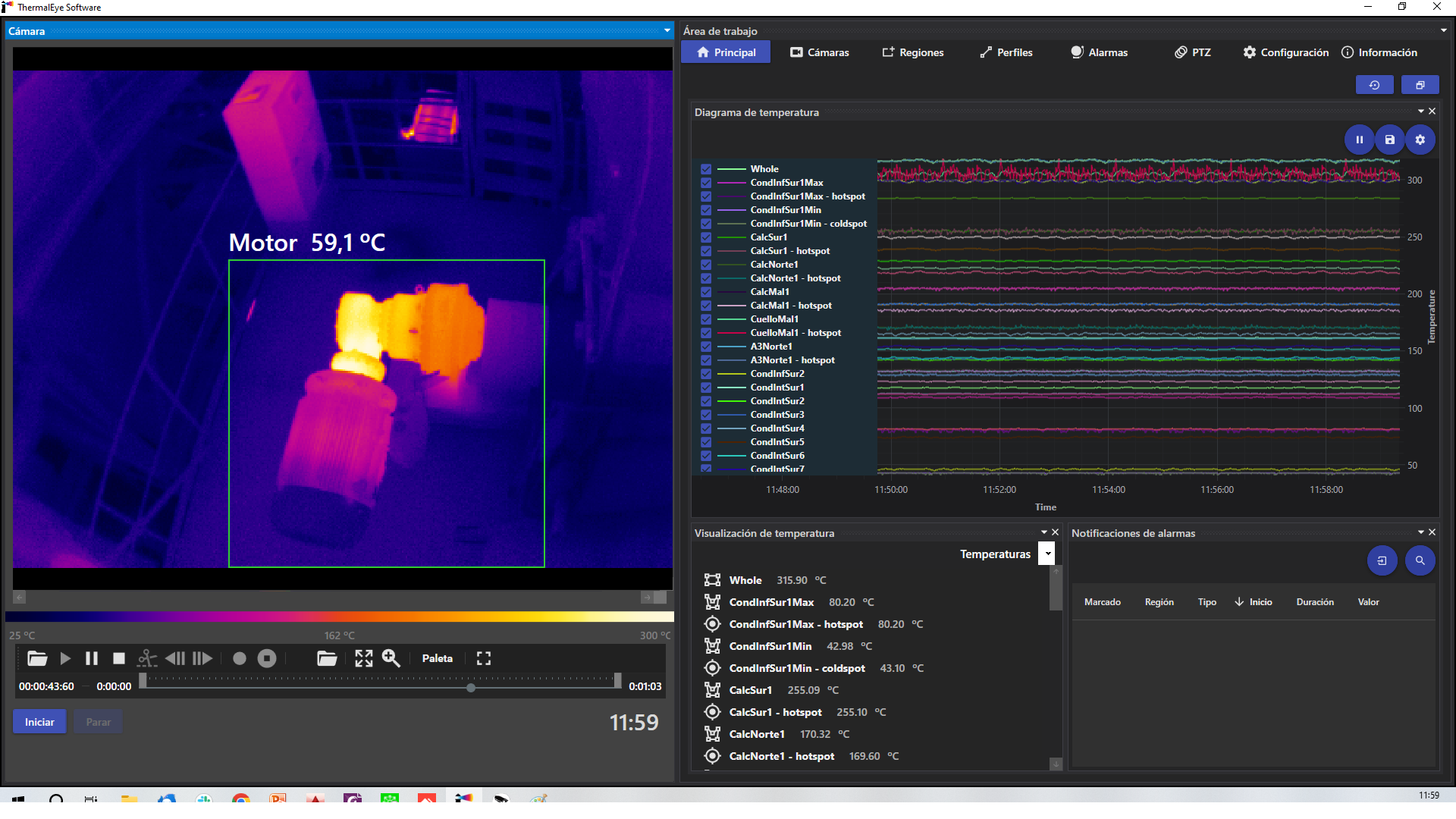

ThermalEye is a modular and flexible temperature monitoring system based in radiometric infrared cameras. The system is able to capture the temperature distribution of a surface in milliseconds with automatic detection of hot and cold spots.

The ThermalEye system is a versatile and highly effective tool for various industrial applications, allowing precise temperature control on the exterior of furnaces, boilers, and glass melting tanks. It provides detailed information about hot spots that could indicate refractory damage. Additionally, its ability to monitor heat or gas leaks, as well as supervise ash deposition hoppers and burners, makes it a key solution for energy optimization. Furthermore, its implementation in evaluating the effectiveness of flare stacks in industrial chimneys significantly contributes to energy savings and enhances plant safety, ensuring efficient operation and reducing operational risks.

Benefits

- 24/7 temperature monitoring in different areas.

- Real-time detection of hot and cold spots.

- Custom installation for temperature control of large surfaces.

- Operation with minimal maintenance.

- Optimal process control.

- Modular expansion. The system can be expanded at any time with more cameras and workstations.

- Suitable for installation in any environment.

- Visualization of any target at any distance with exceptional clarity.

Software

This system enables full remote control of all infrared cameras, ensuring fast and precise temperature measurement in milliseconds. Additionally, it facilitates the automatic detection of hot and cold spots for thermal object evaluation, with advanced inspection zone configurations that optimize parameters such as emissivity, measurement temperatures, alarm events, and dimensions.

Its integration into networks and automated systems is seamless thanks to its advanced interface, allowing recording functions and data analysis. It also offers alarm notifications via email or digital outputs and enables the control and analysis of multiple cameras within a single system for efficient management.

Characteristics

- Monitoring of large areas.

- Definition of alarm zones and related temperatures for each IR camera.

- Precise and comprehensive temperature detection.

- Discrimination system consisting of alarms and pre-alarms to avoid false alarms caused by work vehicles, forklifts, etc.

- High-resolution temperature measurement at long distances.

- Custom system design and architecture. Tailored solutions even for complex monitoring tasks.

- Spatial vision. Visualization of all areas in a map view.

- ATEX-certified enclosures for installation and operation in Ex zones 1, 2, 21, and 22.

Industrial Flare Monitoring

Industrial torches are used for the controlled combustion of excess gases, especially in the chemical and petrochemical industry. Flare monitoring is essential due to regulatory requirements, industrial production efficiency, and safety.

Systems based on thermal imaging cameras are the ideal solution for industrial flare supervision, avoiding many technical and economic issues associated with other technologies, such as ultraviolet (UV) flame detectors, flame ionization spectrometers, thermocouples, and pyrometers.

The ThermalEye imaging system, based on infrared (IR) cameras, is the ideal solution for industrial flare monitoring, providing significant energy savings and enhancing plant safety.

ThermalEye is a modular and flexible temperature monitoring system based on radiometric infrared cameras. This thermography system offers maximum precision and reliability, enabling automated remote monitoring 24 hours a day, 7 days a week, in virtually any weather condition.

Download aplication note ThermalEye

Industry

- Flame monitoring in furnaces.

- Refractory monitoring.

- Gas leakage.

- Air conditioning leaks.

- Coal storage.

- Chemistry and petroleum production.

- Recycling / waste facilities.

- Wood processing.

- Road tunnels.

- Conveyor belts.

- Biomass storage and silos.

- Hazardous environments: flammable substances, ATEX-classified zones.

Do you need advice or a quote?

Contact our team!