High temperature is required for the process where molten glass is transformed into different shapes (glass container, fiberglass, flat glass, special glass, tableware, etc.).

To maintain the temperature, the furnaces are fed slowly and usually operate at temperatures of up to 1,575 °C, limited only by the quality of the material in the furnace itself and by the composition of the glass.

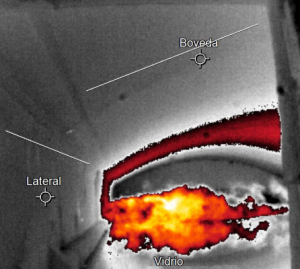

Temperature monitoring is critical to meet the highest standards of quality and reliability.

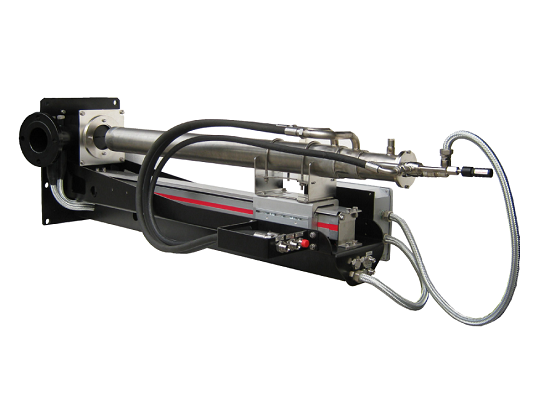

The ProTIR Thermographic Vision System is ideal for glass melting furnaces, allowing you to control and optimize the process, save energy and extend furnace life.

Based on high resolution thermal imaging cameras and specific software, the ProTIR system provides radiometric images in real time where the temperature inside furnaces, coolers and boilers is obtained with high precision.