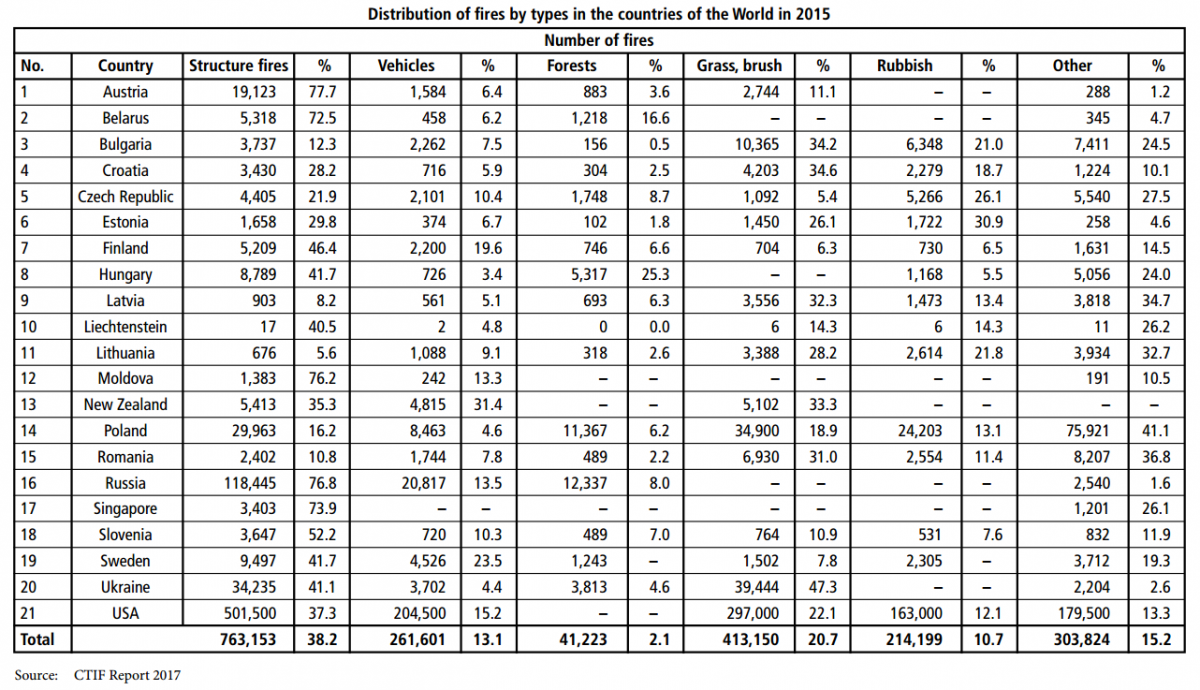

The statistics provided by CTIF (International Association of Fire and Rescue Services) are showing that the fire incidents in the waste sector are very significant, specially in some countries.

Main reason of fires in waste plants

The main reason why fires are happening in waste plants is that there is no early fire detection system.

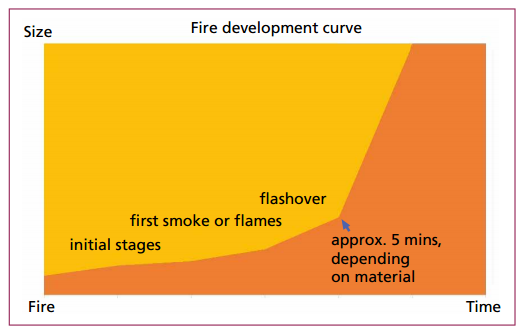

Many waste plants have installed flame, smoke or heat detectors. But those detectors they generate an alarm when the fire, the smoke or high temperature has reached the detector, what means that the fire already had time to develop and spread.

Early detection is the only way to ensure that small fire sources can be extinguished quickly and easily in the initial fire development phase.

Fire detection options

Smoke detectors

Smoke detectors are normally installed in the ceiling of waste treatment areas, so they are installed very high up.

These areas are often open to the sides, which sometimes causes the wind to blow the smoke away from the detectors. If the temperature of the air is high, like in summer, the hot air accumulates under the roof and keeps the smoke out from reaching the detector.

It is not possible for the smoke detectors to distinguish between smoke, that sometimes can be generated by machines or vehicles, and fire, so a large amount of smoke needs to rise to the ceiling before the fire detection system triggers. Ths creates a critical delay before firefihting starts.

Linear heat detectors

Linear heat detectors are sensor cable detectors, often known as thermocouples, and are mainly used to monitor tunnels or garages. These devices detect increases in temperature via changes in resistance.

In waste treatment plants, where linear heat detectors are installed on the ceiling, they will only detect significant temperature change when the heat reaches the top.

Similarly as it happens with smoke detectors, by that time the fire will be already large, so this technology is also not suitable for waste and recycling facilities.

Sprinklers

Sprinklers are triggered when heat causes a liquid to expand in a small glass bulb, which causes the glass tube to burst, releasing extinguishing water. The problem is that it requires a temperature of at least 70°C to cause the glass bulb to burst.

When installed on the ceiling in waste treatment plants, each sprinkler normally protects an area of several square meters. In this case also the heat must reach the detector in order to trigger the extinguishing process, what means that the fire has already developed substantially.

Thermography System for Early Fire Detection

FireTIR System

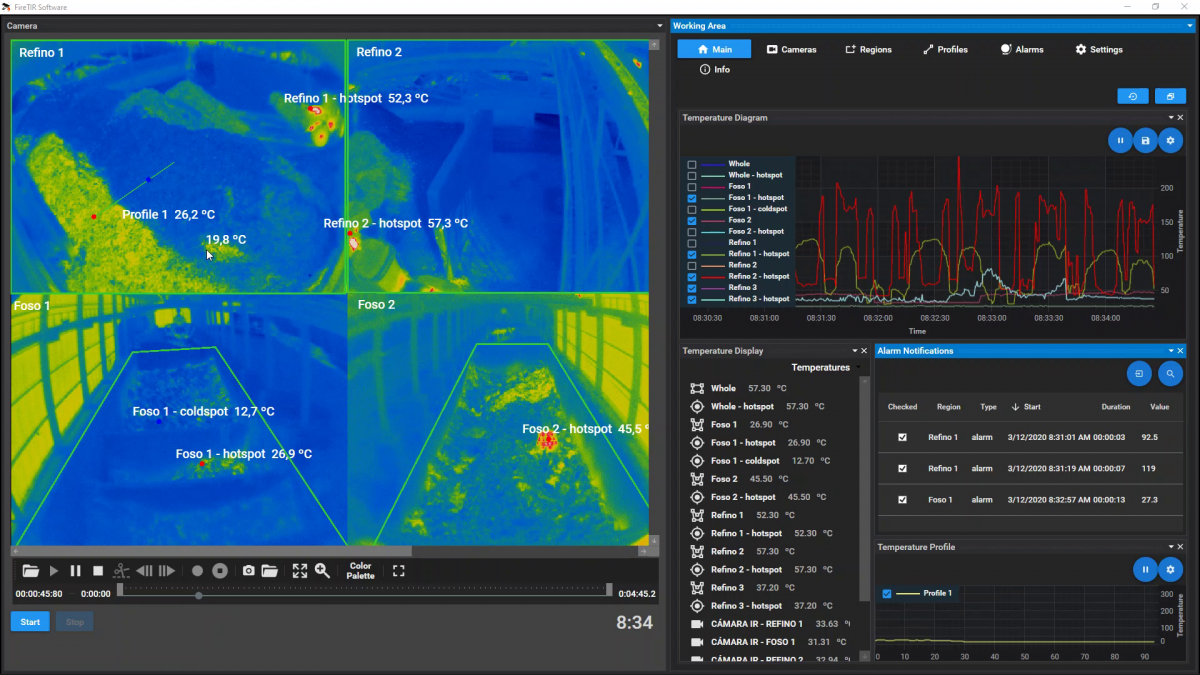

FireTIR is a thermography system using infrared cameras for early fire detection. The system provides real time temperature monitoring in waste to energy and waste management plants, capturing the temperature distribution of the area in milliseconds, with automatic detection of hot spots.

FireTIR system performs the monitoring based on the images and data captured by infrared cameras pointing to areas where there are solid waste stacks, in both indoor and open-air areas.

FireTIR Software

FireTIR Software offers full remote control of all infrared cameras, different inspection zones configuration, recording functions, alarms and analysis of the measured data.

FireTIR allows an easy integration with other systems like plant safety, firefighting, production control,…