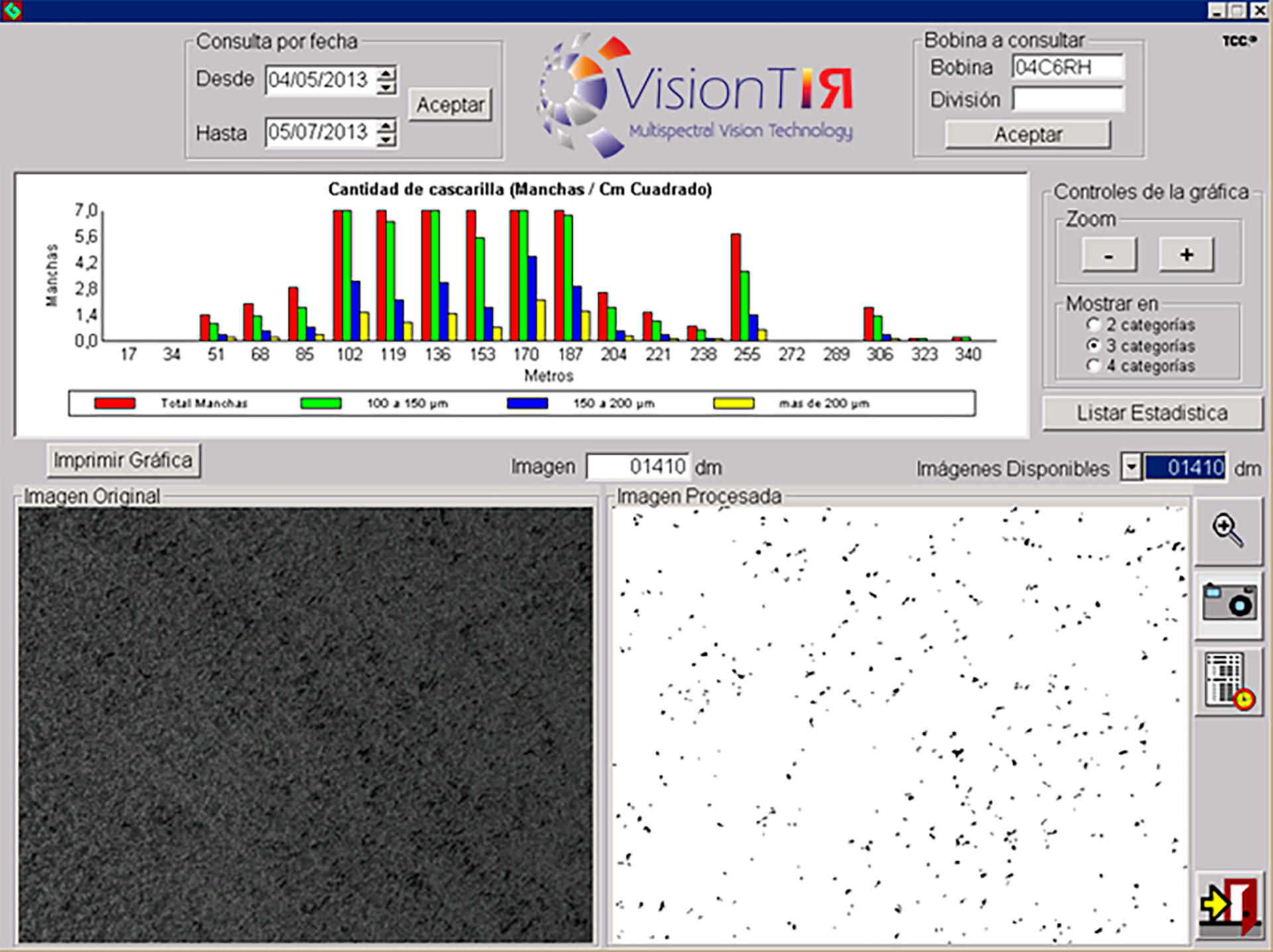

MCQC100 – Metal Coils Quality Control System for real time detection, classification and visualization of defects.

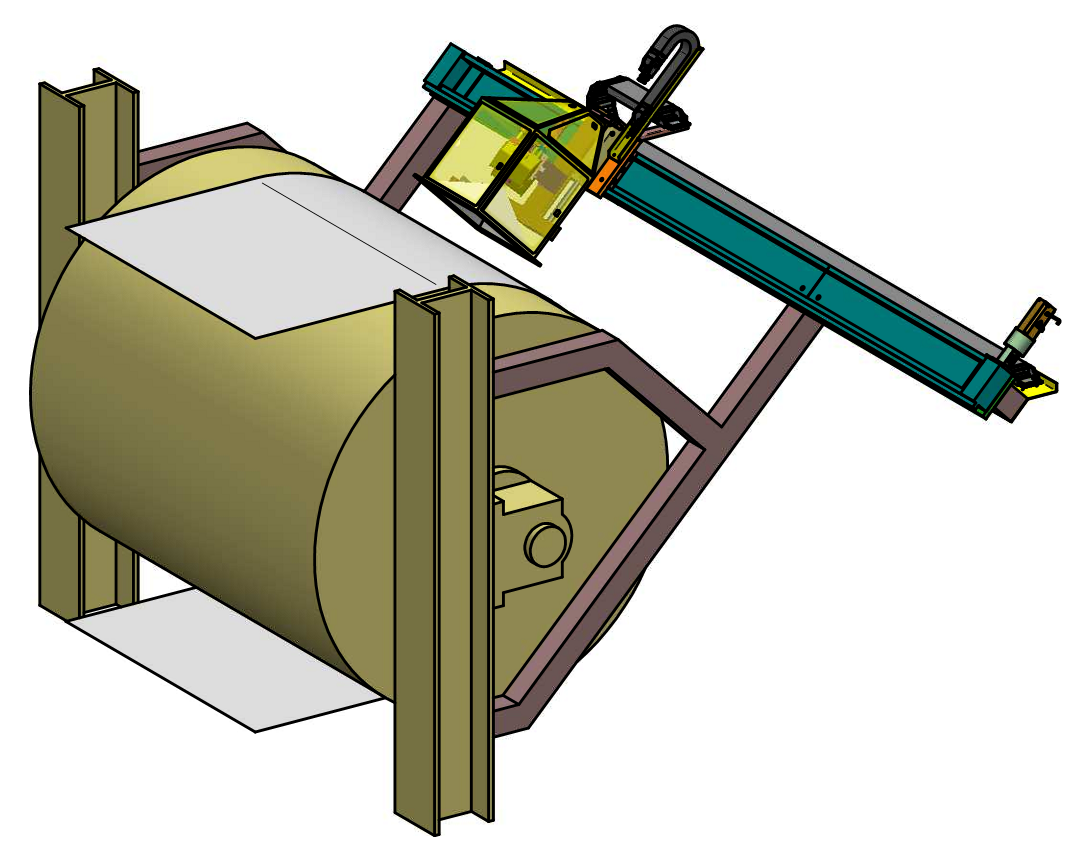

MCQC100 is an automated quality control system for surface defects detection, classification and visualization in cold-rolling mills. MCQC100 inspection is performed on a random sampling of the material surface. It provides an objective assessment of the product`s surface quality and helps the operator in the fine adjustment of the production process.

The integration of the MCQC100 system in the architecture of the factory provides tools to assist Quality Personnel on making decisions and guide the optimization of the production process.