Practical guide to identify fire classes (A, B, C, D, F/K and electrical) in industrial environments and apply the correct extinction method. Includes standards differences and prevention with thermography.

Industrial safety · Practical guide

Types of Fires: How to Identify and Combat Them in Industrial Environments

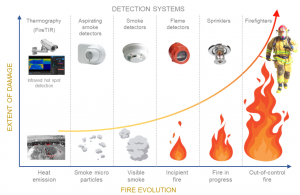

Anticipating fire is the best strategy. Early detection of thermal anomalies prevents material damage, production downtime and risks to people. When a fire does occur, identifying its type and behavior is key to applying the right extinction method.

As experts in thermography applied to fire prevention and detection, at VisionTIR we know that each fire class requires a specific action strategy. Early identification can make the difference between a controlled incident and a major loss. Understanding fire typology helps select the right detection/extinction systems and establish effective industrial safety protocols.

Fire types and recommended extinction methods

Class A Fire: solid combustibles

Extinction methods

- Water (cooling the material).

- Foam or ABC dry chemical extinguishers.

Examples: warehouses, paper mills, carpentries, recycling plants.

Class B Fire: flammable liquids

Extinction methods

- CO₂, dry chemical (ABC) or foam extinguishers.

- CO₂ works by smothering (removing oxygen).

- Dry chemical interrupts combustion by breaking the chain reaction.

Examples: refineries, chemical plants, hydrocarbon depots.

Class C Fire: flammable gases

Extinction methods

- CO₂ or dry chemical (non-conductive).

- Never use water.

Examples: gas plants, energy facilities, processes with pressurized gases.

Class D Fire: combustible metals or chemicals

Extinction methods

- Special powders for metals (e.g., sodium chloride or graphite).

Examples: metallurgy, foundries, lithium batteries, chemical industries.

Class F / K Fire: oils and fats

Extinction methods

- Wet chemical (Class K) extinguishers: cool the grease and smother the flame, preventing re-ignition.

Examples: industrial kitchens, food plants, oil refineries.

General extinction methods

Besides specific systems for each fire class, there are three basic principles applicable in most cases:

Cooling

Reduce the fuel temperature, usually with water or refrigerants.

Most common in Class A fires.

Smothering

Remove or reduce the oxygen available for combustion.

Achieved with foam, CO₂ or covering the flame.

Inhibition

Interrupt the chain reaction using chemical agents.

Effective in Class B and C fires.

Understanding these principles helps design an integrated strategy for prevention and extinction tailored to each industrial environment.

Differences between classification standards

Europe uses EN 2 / ISO 3941, while the US uses NFPA 10. Key differences:

| Category | Europe (EN 2 / ISO 3941) | US (NFPA 10) |

|---|---|---|

| Flammable gases | Class C | Included in Class B |

| Electrical fires | Separate category (not a fuel class) | Class C (energized equipment) |

| Cooking oils & fats | Class F | Class K |

The key is anticipation: early detection with thermography

Early fire detection is the most effective tool to avoid human and material losses. Infrared thermography identifies abnormal temperature rises before combustion starts.

With continuous, non-contact monitoring, VisionTIR systems detect fires at their earliest phase, even before embers or smoke appear.

In recycling plants, cement plants, fuel storage, electrical facilities or logistics centers, VisionTIR’s thermography provides precise, reliable and preventive detection to act before a fire occurs.

Do you want to reduce fire risk at your plant? Implement early detection with infrared thermography. Contact us and design a customized solution.

Quick questions

What method is most common in Class A?

Cooling the material with water or refrigerants.

How is smothering performed?

By reducing oxygen: foam, CO₂ or covering the flame.

What should not be used on Class C or electrical?

Do not use water or conductive liquids. Use CO₂ or dry chemical powder.