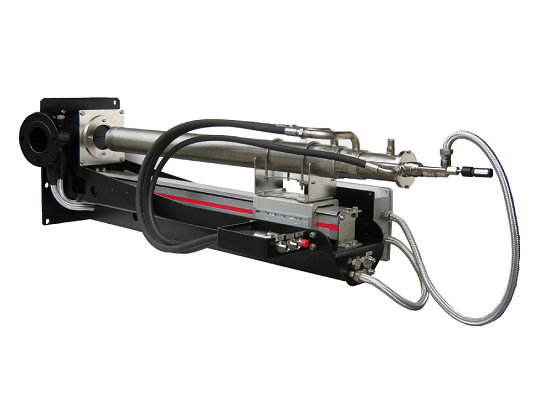

ProTIR® – Infrared Thermal Imaging System for continuous temperature monitoring.

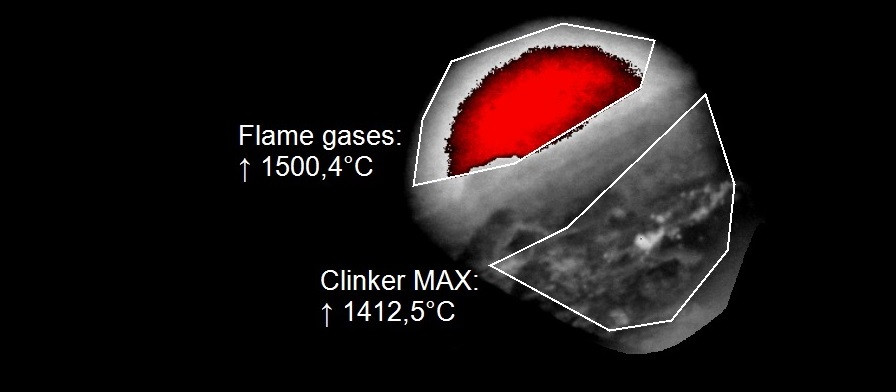

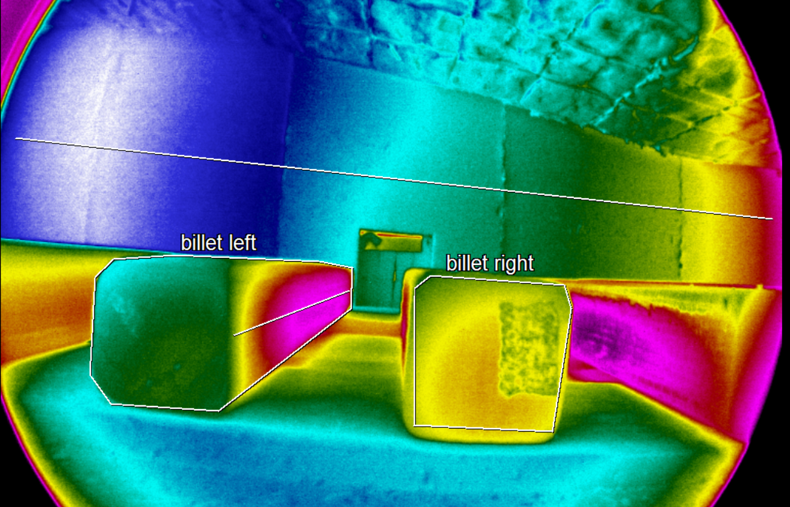

Based on high resolution thermal cameras and a specific software, ProTIR® provides real radiometric images that accurately measure temperature inside of furnaces, rotary kilns, coolers, incinerators and boilers in the steel, minerals, power generation and process industries.

In addition, ProTIR® is also ideal for glass melt furnaces, steam reformer and cracker tube furnaces, enabling process control optimization, energy efficiency savings and prolonging the lifetime of the furnaces and reformer tubes.

With 86º viewing angle optic, our system provides accurate temperature information (from any of 367,000 live data points) of an extensive area with just a narrow opening in the wall.

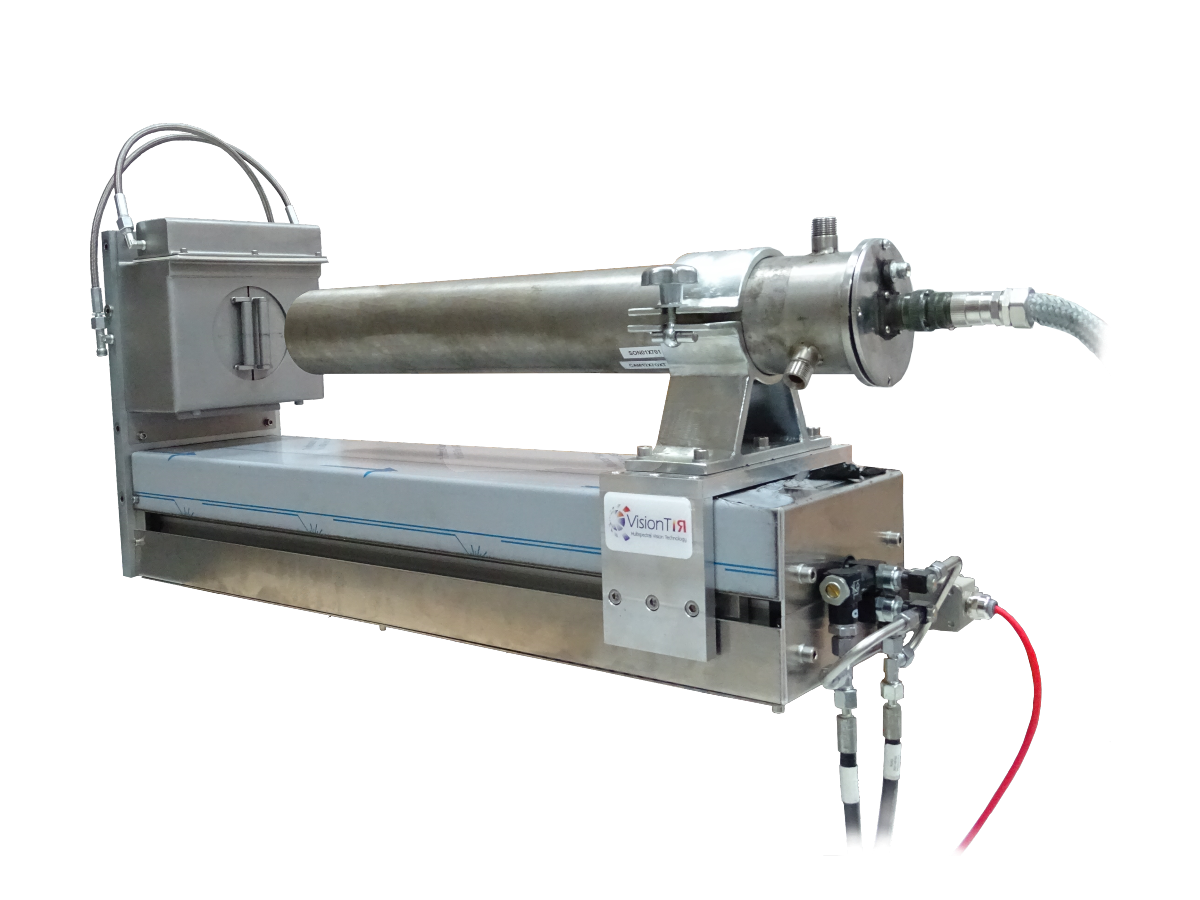

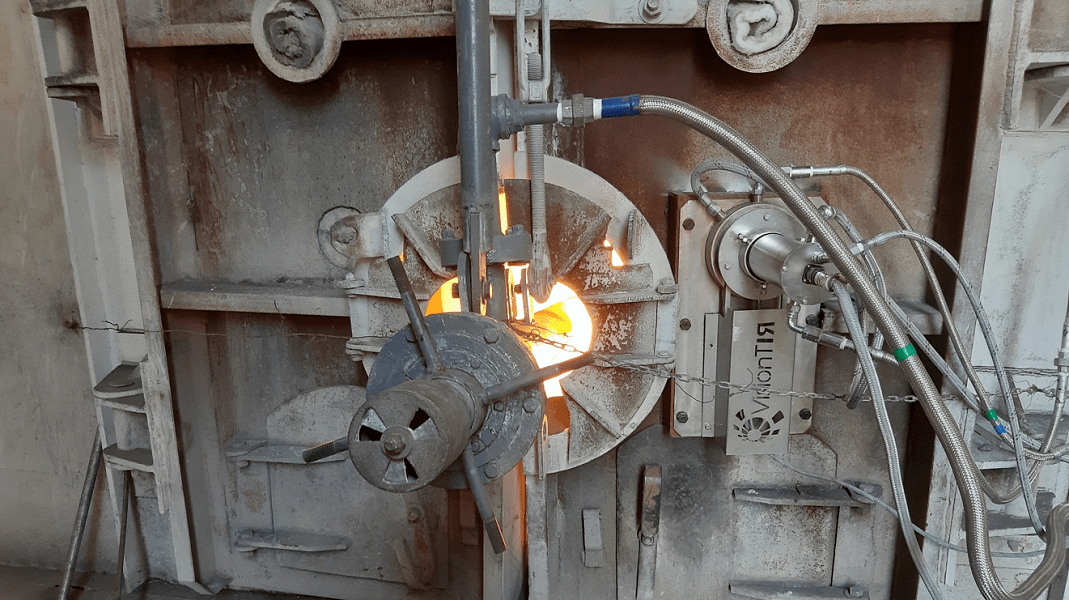

Protected by a rugged protective housing and using a high-performance water-cooling system, ProTIR® system resists up to 2.200 ⁰C (3,992ºF). In addition, our thermal imaging solution provide a wide temperature measurement range of 450 – 1800 ºC ( 842 – 3272 ºF).

ProTIR® software provides accurate data analysis along with automated alarm outputs and control for 24/7 monitoring, to instantly alert the user of any problems from the control room.