Clinker cooling process

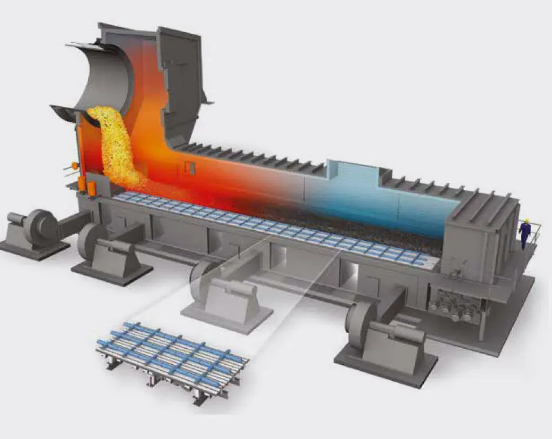

A very important process during cement production is the cooling of the clinker, since to a large extent the quality and characteristics of the cement depend on this phase.

The hot clinker produced in the rotary kiln is transferred to a cooler, where it is cooled by air blowers before being conveyed to the cement mill.

In the clinker cooler, the hot clinker is rapidly cooled by air in order to obtain a high degree of efficiency. Modern clinker coolers have an air flow perpendicular to the clinker flow, absorbing thermal energy. This hot air is used almost entirely as secondary air for combustion in the rotary kiln, or as tertiary air to the tertiary air duct.

Clinker temperature control

It is critical to monitor the temperature of the clinker searching for those hot spots in the material with a temperature above a set threshold before it reaches the conveyor causing damages.

Including material that is too hot together with the cooled clinker could cause a conveyor fire, damages to equipment, and stops in the cement manufacturing process. To avoid this problem, it is necessary a high-resolution temperature monitoring system with a rapid response capable of detecting hot spots even if they are very small.

Snowmen in the clinker cooler

Snowmen are formations of large buildups on the cooler’s first (static) grate or the kiln discharge wall where the clinker falls from the kiln. They occur in deposits formed from small clinker nodules and clinker dust particles with a chemical and mineralogical composition identical to clinker, but in some cases with enrichment up to 3.5 per cent K2O and three per cent SO3 has been noticed. Snowmen cause poor clinker distribution, leading to a ineffective heat exchange between clinker and secondary air.

Some cement plants incorporate into the cooler a boroscope inspection camera in the visible spectrum to inspect the cooler’s interior and identify the so-called “snowmen”. However, due to the amount of smoke and gases inside the cooler, borescopes are often not able to reliably detect snowman formation.

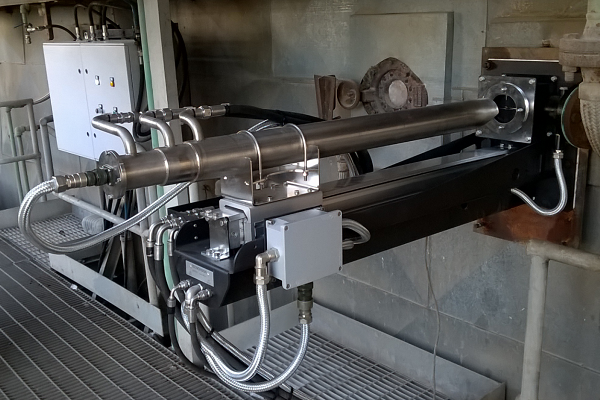

ProTIR thermographic vision system

ProTIR is a thermographic vision system that allows you to quickly detect any clinker particles that have not cooled sufficiently, preventing potential fires or damage to the conveyor belt. In addition, by monitoring the temperature, ProTIR ensures that the cooling process is correct.

The thermal imaging camera-based ProTIR system is operated at the high temperatures (200-1000°C) generated within the cooler, providing real-time thermal imaging.

The thermal images and temperature measurements provided by the ProTIR system faithfully reproduce what is happening inside the cooler and help the operator to detect the formation of the snowman. Due to the heat resistance of the equipment up to 2200°C, the installation inside the cooler is possible.